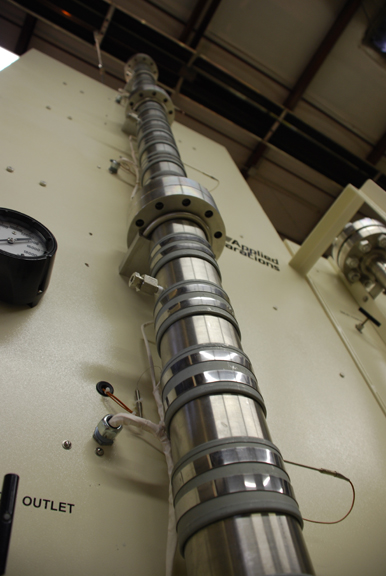

Applied Separations constructs unique counter-current extraction columns that use supercritical carbon dioxide to fractionate components contained in a liquid feed. Counter-current extraction using supercritical carbon dioxide is an alternative to conventional distillation and solvent extraction for purification of components of low volatility. This process offers the use of a “green solvent” with enhanced selectivity and mild operating conditions.

Counter-current separation achieves a multistage separation. This scheme reduces the amount of CO2 consumed, increases product concentration and is operated continuously. Various components in the feed distribute between the CO2 solvent (extract phase) and the liquid (raffinate phase) which counter currently flow through the separation column. This type of multistage separation is absolutely necessary for achieving a reasonable separation between two substances with a relatively low separation factor.

Many applications of this technology are useful in the food processing industry. For example, the following compounds have been separated from many different edible oils: free fatty acids, glycerides, free fatty acid ethyl esters, squalene, EPA and DHA, and tocochromanols. In addition, terpenes have been removed from many citrus oils including lemon and orange by the counter-current technique.

- Integrated into solids system

- Pressure: 680 BAR

- Temperature: 150oC

- Feed flow rate: 0.1-1.0 kg/min

- 6 liters, 3 meters, expandable

- 3 Temperature zones

- 3 independent in/out ports