Patented Emergency Pressure Relief Device

Applied Separations makes supercritical fluid systems even safer with their specially developed and patented device to relieve the pressure in a vessel when the normal inlets and outlets have been clogged after extraction/reaction conditions.

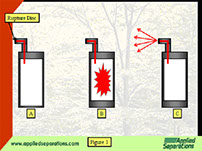

Standard Pressure relief devices have been in use for years to prevent a catastrophic failure of a pressure vessel. These can take the form of pressure relief valves or rupture discs (A). When the pressure rises to the established limit point (B), the valve opens or the rupture disc fails and the pressure is reduced (C). The situation shown in Figure 1 is the common response to overpressure conditions.

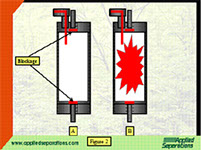

Figure 2 illustrates a situation in which an extraction/reaction has been performed causing blockage of the inlet or outlet ports (A). The pressure is not great enough to exceed the relief pressure of the rupture disc, but the contents in the pressure vessel are under pressure (B), resulting in an UNSAFE CONDITION.

Often a user may attempt to relieve this unsafe condition by trying to forcibly remove the cap by opening it just a small distance so that the pressure can be bled off. This is usually difficult to do, both in overcoming the pressure and in stopping the forced opening at exactly the right point. The usual result is that the cap is blown off like a cork from a champagne bottle but with far more dangerous consequences (Figure 3).

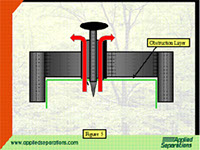

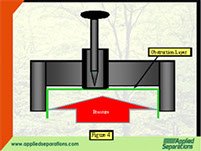

Applied Separations, Inc.’s patented device eliminates the problems associated with this “contents under pressure,” but not overpressure condition. Because of an obstruction on the inside of the pressure vessel, the contents are under pressure, (Figure 4). Shown here is the patented relief device that pierces the obstruction layer.

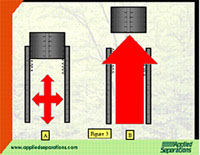

Turning the knob drives the piercing element through a rupture disc and the obstruction layer (Figure 5), allowing the vessel to depressurize safely. Should the obstruction layer reseal, the process can be repeated continuously until the pressure is released.

The threaded Emergency Pressure Relief Device is simply screwed into one of the unused ports in the vessel end caps, or in the vessel’s sidewall.